ABOUT US

Interesting facts about Crumpler

Discover more about us and our products

What makes us different

Our passion - we have bags in our blood

Why do we make bags? Because it's what we do best. Since our first messenger bag, we have strived to offer the perfect bag for every type of city dweller - from the street photographer to the traveler, from the tech enthusiast to the commuter. We are constantly tinkering and constantly optimising our bags in order to be able to offer the best possible solution for every situation.

Details - what separates the good from the great

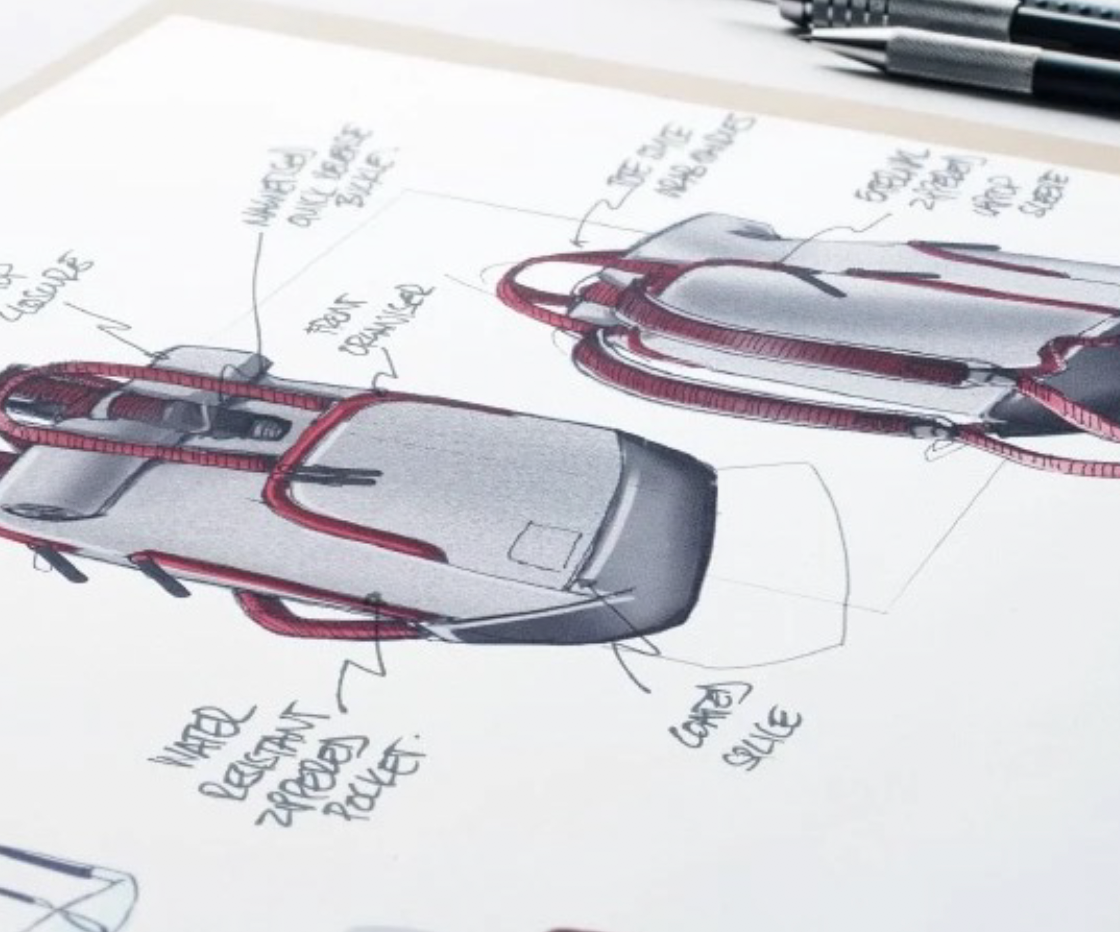

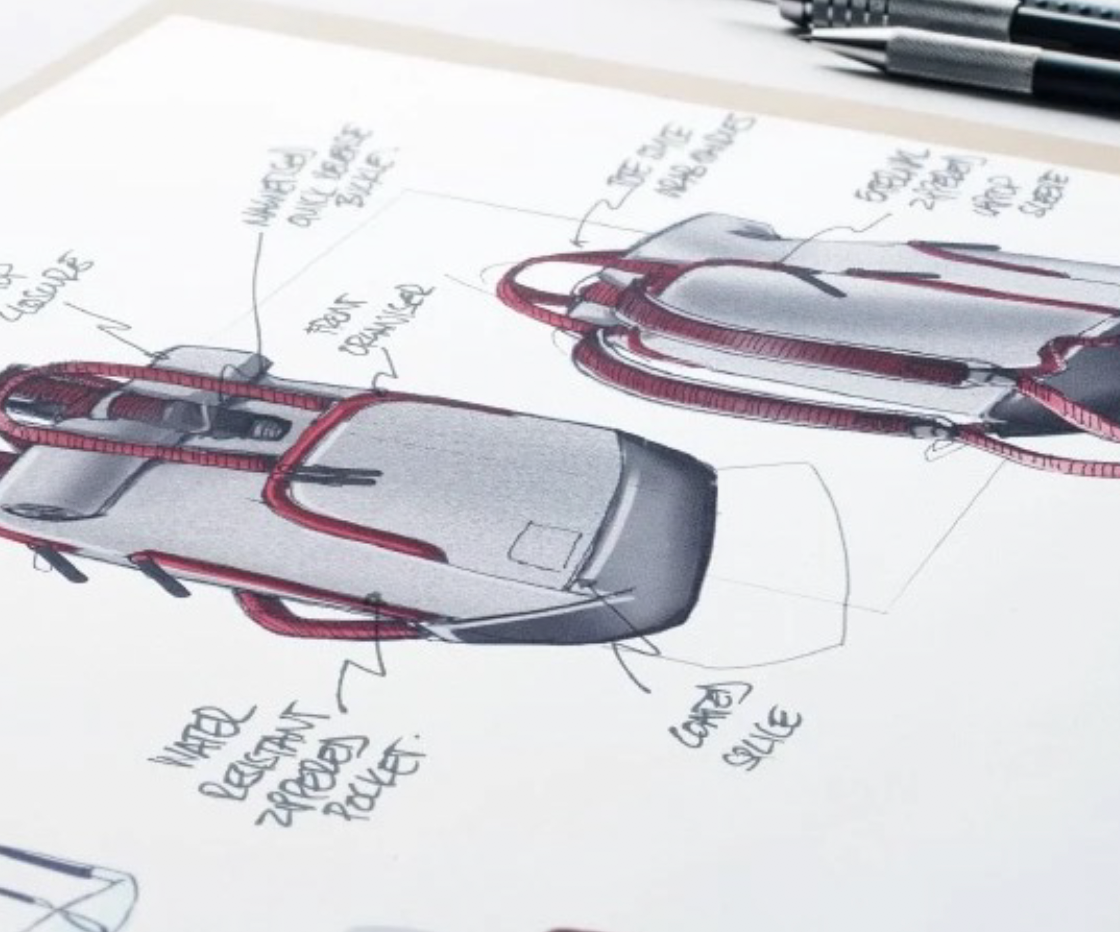

Our bags take forever to finish. It usually takes a year from concept to release, which is in complete contrast to the rest of the fast-paced fashion world.

But trends come and go. But we are here to stay and we are simply not good at making compromises. But you certainly aren't either, are you? We make real bags for real people. People who appreciate quality.

Quality - great love and no one night stand

We make bags that we are proud of and that are made to withstand the toughest conditions.

Word has gotten around that we are committed to quality. That's why we've been able to build up a large base of loyal Crumpler fans over the years.

Function - Funk Yeah!

Looks are important, but not everything. That's why we spend a lot of our time working on the soul of our bags: the functions.

We believe that a bag is an extension of your body and helps you achieve your daily goals. Of course, we want to give you the best possible support.

The Crumpler Difference

Our bags are designed for all occasions of an urban lifestyle. They are characterised by superior quality, the use of diverse, high-quality materials and a clear focus on functionality. Whether on the way to university or the office or in your free time: our bags and backpacks not only look good, but are also incredibly practical and well thought out. Numerous useful and functional features and stylish design make our bags the perfect companions for work and leisure. Highly functional materials ensure that laptops, IT gadgets, cameras, etc. reach their destination safely.

Our approach to developing our bags can best be described as “function meets fashion”. We design and produce ourselves and have many years of proven know-how. We simply know how to design and manufacture bags. This pioneering spirit - discovering new things, questioning and improving what already exists - is still the starting point and driving force behind the design of every new Crumpler bag. When it comes to manufacturing techniques, we focus on maximum durability and strength. After all, there is no point in using the strongest and most durable material if it is not processed in the most sustainable and best way.

Crumpler bags are "Built for purpose & made to last."

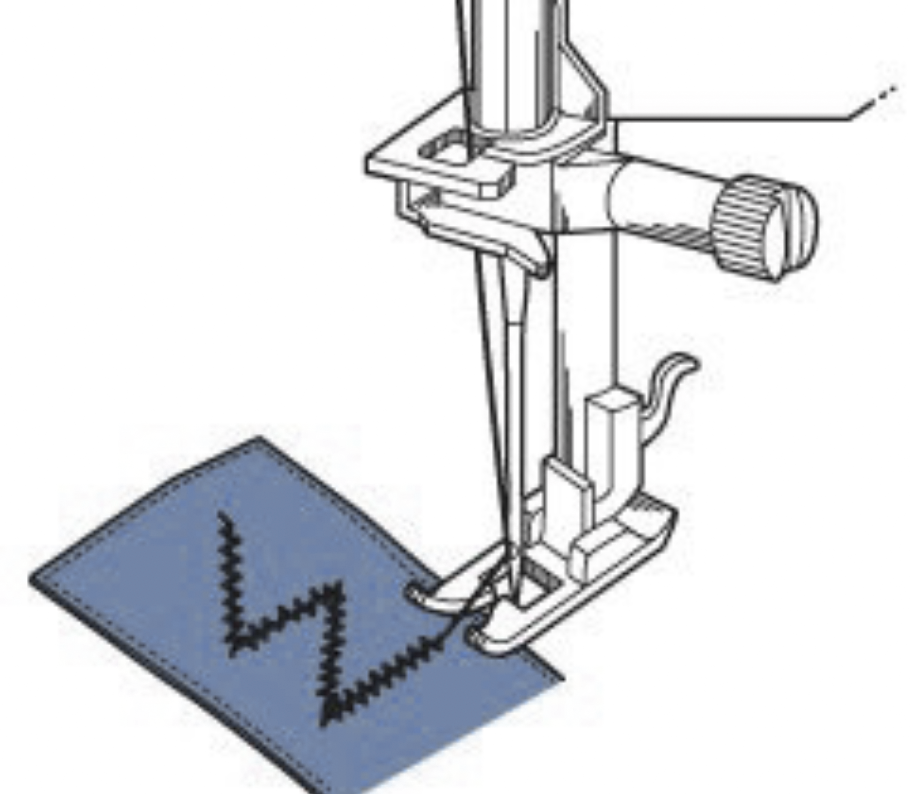

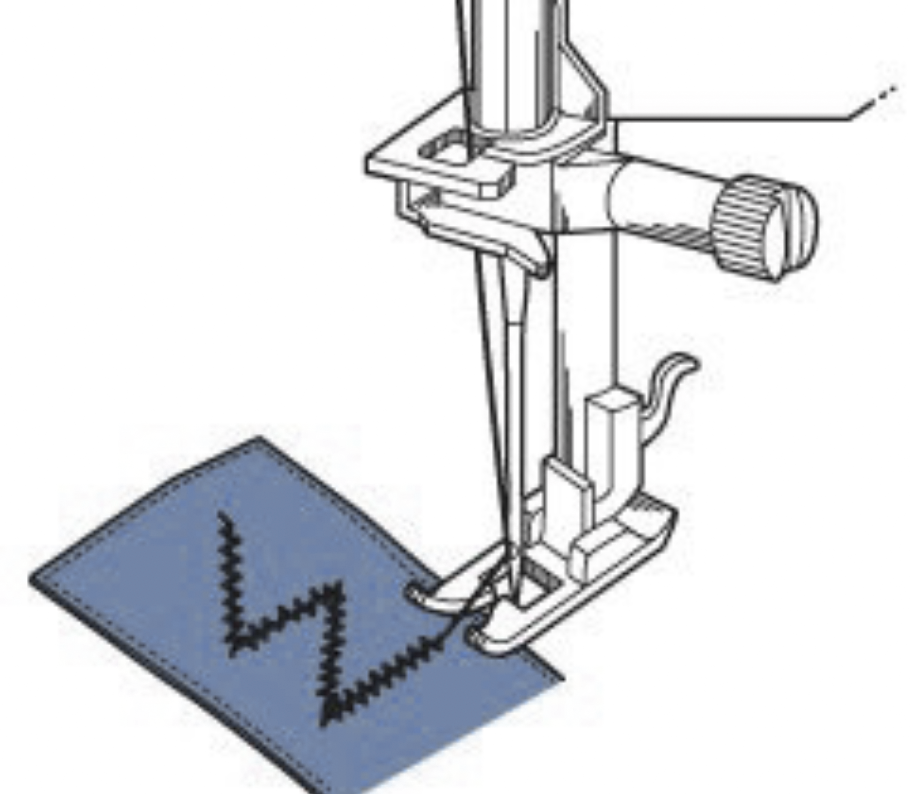

In order to make a bag really durable and resilient, you need strong seams in the crucial places.

We use the so-called bar tack, a series of extremely dense seams that are sewn at a 90 degree angle to each other. They are everywhere, even in places where you can't see them, and ensure that our bags pass every stress test.

Unlike some outdoor brands, we do not use overly complex or complicated buckles or fasteners. We use extremely strong and efficient closures for our bags. These are made of either polyamides (nylon) or polyacetal, a material that is often used as a replacement for metal.

All of our closures are made specifically for Crumpler and are of course subjected to constant quality tests.

We use both nylon and polypropylene fabrics. This fabric is created from a flat band of fibers of different thicknesses that are woven in several layers. The resulting net-like construction gives the material its name (web = webbing).

The fabric we use is extremely strong. It can withstand a load of up to 4500kg without tearing. For example, with our 50mm webbing you could pull a car without any problems.

We add additional piping (round cord piping) and binding (edging) to our bag. A single piping is attached with four additional seams, even if only two of them are visible from the outside. We don't just do this because it looks good, but also because it reinforces all the seams and edges and makes the Crumpler bag even more robust.

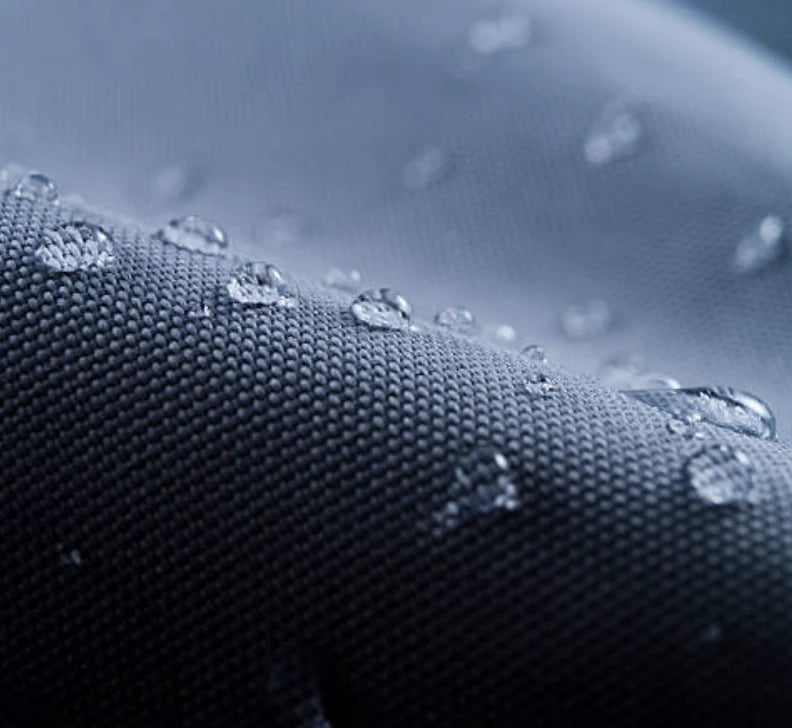

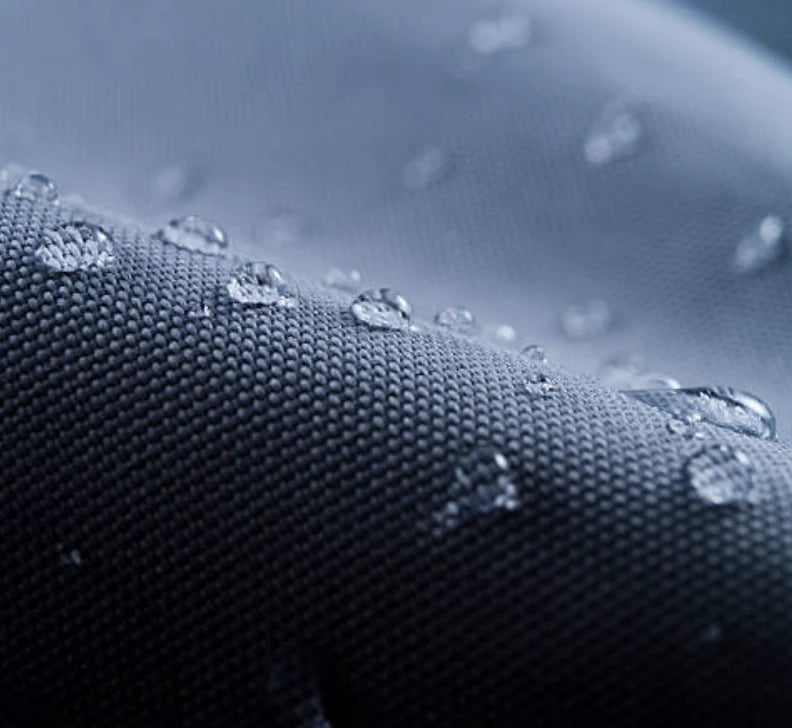

All Crumpler materials are coated and specially treated to achieve maximum water repellency and high resilience. For example, we use a PU backing on the back of our materials and a water- and dirt-repellent coating on the front.

These coatings make our material work even better and are even easier to use, especially in complicated areas where the strength of the material is the main issue. The coatings also offer maximum protection against dirt and dust.

Crumpler employs a team of several independent quality inspectors. These inspectors accompany the entire production process and ensure that our products are processed perfectly.

The quality is constantly checked during each individual production step. The sewers and seamstresses check each individual piece as it is being sewn. Everyone checks whether the piece of the bag they are currently working on was properly processed in the previous step. Only then will it be further processed. After completion, every single Crumpler bag is checked in detail before it is packed.

Now it's getting personal! Many of our Crumpler bags can be personalised. There are 46 high-quality letters and symbols to choose from.

Your 3 selected letters or symbols will be configured by hand according to your specifications before delivery. This turns your product into something individual, unique and special.

“Different & better” – that is the basis on which the entire Crumpler design rests. We are our own brand with our own team, our own style, our own design, and we love the bags we make. By focusing on designing bags independently of short-lived fashion trends, we are able to design products that outlast seasonal trends.

Our bags are made to last for decades. Of course, this means that the design can't look like it's from last season. Our products have already won several international design awards.

We spend a lot of time developing new, complex samples until all ideas are implemented and they are ultimately used as a template for one of the expressive and high-quality bags that the Crumpler name stands for. Just like the very first Crumpler bag, all our bags are made by hand.

We have no automated sewing processes. For one of our earlier bags, our "Track Jack Board Case", we have translated this into numbers: In each of these board cases,

- 186 individual parts

- 389.2 metres of thread

- and 21.3 metres of webbing

- were processed in 160 work steps

This corresponds to approximately 6.5 hours of pure manual labour to produce a single bag!

Sustainability has always been important to us. We offer many products in our range made from recycled materials, which are manufactured from various post-consumer and post-industrial materials.

As a conscientious manufacturer of bags, we are aware of our responsibility for the entire life cycle of our products. Our aim remains to design and produce innovative and sustainable products in order to minimise the negative impact on our environment.

Made to Last: We focus on robustness and durability. This is just as important to us as the use of recycled materials, because for us, sustainability also means that our products last a long time and are used for a long time.

In order to make a bag really durable and resilient, you need strong seams in the crucial places.

We use the so-called bar tack, a series of extremely dense seams that are sewn at a 90 degree angle to each other. They are everywhere, even in places where you can't see them, and ensure that our bags pass every stress test.

Unlike some outdoor brands, we do not use overly complex or complicated buckles or fasteners. We use extremely strong and efficient closures for our bags. These are made of either polyamides (nylon) or polyacetal, a material that is often used as a replacement for metal.

All of our closures are made specifically for Crumpler and are of course subjected to constant quality tests.

We use both nylon and polypropylene fabrics. This fabric is created from a flat band of fibers of different thicknesses that are woven in several layers. The resulting net-like construction gives the material its name (web = webbing).

The fabric we use is extremely strong. It can withstand a load of up to 4500kg without tearing. For example, with our 50mm webbing you could pull a car without any problems.

We add additional piping (round cord piping) and binding (edging) to our bag. A single piping is attached with four additional seams, even if only two of them are visible from the outside. We don't just do this because it looks good, but also because it reinforces all the seams and edges and makes the Crumpler bag even more robust.

All Crumpler materials are coated and specially treated to achieve maximum water repellency and high resilience. For example, we use a PU backing on the back of our materials and a water- and dirt-repellent coating on the front.

These coatings make our material work even better and are even easier to use, especially in complicated areas where the strength of the material is the main issue. The coatings also offer maximum protection against dirt and dust.

Crumpler employs a team of several independent quality inspectors. These inspectors accompany the entire production process and ensure that our products are processed perfectly.

The quality is constantly checked during each individual production step. The sewers and seamstresses check each individual piece as it is being sewn. Everyone checks whether the piece of the bag they are currently working on was properly processed in the previous step. Only then will it be further processed. After completion, every single Crumpler bag is checked in detail before it is packed.

Now it's getting personal! Many of our Crumpler bags can be personalised. There are 46 high-quality letters and symbols to choose from.

Your 3 selected letters or symbols will be configured by hand according to your specifications before delivery. This turns your product into something individual, unique and special.

“Different & better” – that is the basis on which the entire Crumpler design rests. We are our own brand with our own team, our own style, our own design, and we love the bags we make. By focusing on designing bags independently of short-lived fashion trends, we are able to design products that outlast seasonal trends.

Our bags are made to last for decades. Of course, this means that the design can't look like it's from last season. Our products have already won several international design awards.

We spend a lot of time developing new, complex samples until all ideas are implemented and they are ultimately used as a template for one of the expressive and high-quality bags that the Crumpler name stands for. Just like the very first Crumpler bag, all our bags are made by hand.

We have no automated sewing processes. For one of our earlier bags, our "Track Jack Board Case", we have translated this into numbers: In each of these board cases,

- 186 individual parts

- 389.2 metres of thread

- and 21.3 metres of webbing

- were processed in 160 work steps

This corresponds to approximately 6.5 hours of pure manual labour to produce a single bag!

Sustainability has always been important to us. We offer many products in our range made from recycled materials, which are manufactured from various post-consumer and post-industrial materials.

As a conscientious manufacturer of bags, we are aware of our responsibility for the entire life cycle of our products. Our aim remains to design and produce innovative and sustainable products in order to minimise the negative impact on our environment.

Made to Last: We focus on robustness and durability. This is just as important to us as the use of recycled materials, because for us, sustainability also means that our products last a long time and are used for a long time.